PaveDrain: Generation 2 of Permeable Pavement

In a previous article we spent a bit of time analyzing the failings of brand new, perfectly installed Generation 1 permeable pavement systems. With the arrival of Generation 2 permeable pavement systems better options are commercially available. With 4+ million SF installed, Generation 2 systems are becoming the preferred option of folks looking to finally solve their stormwater problems, while doing less maintenance.

Generation 1 vs. Generation 2

Generation 1 permeable pavement systems are conventional paving systems that are made permeable. Small holes in the pavement or joints allow water to percolate into the soil. These systems tend to fail quickly because the small holes clog quickly.

Generation 2 permeable pavement systems were designed first to handle water and then converted to pavement systems. By embracing water these systems have larger, more direct channels for water to percolate in.

Advantages of Generation 2 Pavement

Generation 2 represents a clear step forward in addressing stormwater challenges. Generation 2 systems perform better, require less maintenance, and can be used in all roadway options better addressing the challenge of runoff at its source.

| Generation 1 | Generation 2 | |

| Traffic Rating | Light Car Traffic | All Vehicle Traffic |

| Initial Infiltration Rate (in/hr) | 200-600 | 1,600 |

| Maintenance Effectiveness (% of Initial Infiltration Restored) | 20%–50% | >90% |

| Maintenance Interval | Every 3 Months | Every 24 Months |

| Soil Limitations | Yes | No |

| Lifetime | 10 years: Asphalt/Concrete 35 years: Pavers |

35+ years |

| Manufacturer Warranty | No | Yes |

Pre-Clogging

Permeable pavers are among the closest analogs to Generation 2 systems. However they differ greatly in how they are constructed. Permeable pavers rely on compression across the surface to make them function. This means ribbon curbs must be placed around the edge and that crushed rock is placed in the joints. These practices best ensure that load forces are distributed across the pavement surface. The filling of joints though significantly limits the speed at which water can infiltrate, and helps accelerate the clogging process. Simply put: material in the joints pre-clogs the joints and makes them fail quicker.

Generation 1 interlocking permeable pavers are designed to have material in the joint, and will fail quickly without it.

Model Generation 2 System: PaveDrain

Initial Performance

Better design of Generation 2 permeable pavement systems has led to systems that handle water much better. In the two stills below from two separate tests: water runs no more than 3 blocks (3 feet) from where it first hits the surface. The presence of open joints means these systems can take on close to 2,000 in/hr of water. In practice this means that these systems can handle significant amounts of run-on even during very intense storm events (1″-2″ /hr) 100-200:1.

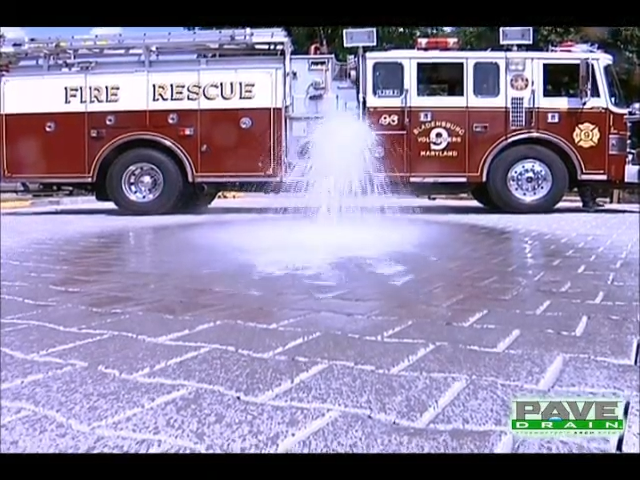

PaveDrain takes on 550 gallons of water in 75 seconds! (Source: www.youtube.com/watch?v=NWPKYRQY70c)

The limit of PaveDrain is actually how quickly the fire truck can dump it’s water (Source: www.youtube.com/watch?v=Gl1jcK_LyMU)

Comparative Performance

The real test of a system isn’t what it does on Day 1 under perfect conditions, but rather what it does 2+ years on. The video below makes it abundantly clear what works best in the field.

| System | Infiltration Rate (in/hr) |

| Permeable Paver (Gen 1) | 3.2 |

| Pervious Concrete (Gen 1) | 2.4 |

| Porous Asphalt (Gen 1) | 3.1 |

| PaveDrain (Gen 2) | 1,640 |

Credit

Interested in learning about how agencies are crediting these superior systems: click here

Conclusion

Time to step up to Generation 2 permeable pavement to better manage your stormwater challenges.

Interested in learning more about the PaveDrain system?

VP of Business DevelopmentAaron Fisher

Latest News

4 Ways To Reinforce Concrete

Concrete is one of the most fundamental materials used in construction. If you’re working on a domestic project or a […]

The Environmental Benefits Of Using Ready-Mix Concrete

The construction industry is changing quickly to meet the growing demand for sustainability and eco-friendly practices. One of the most […]

6 Essential Tips For Grouting Stone Veneer

Grouting stone veneer is an important step in the installation process that can significantly impact the overall look and durability […]

Should You Fill Hollow Concrete Blocks?

Hollow concrete blocks are widely used in construction due to their strength, versatility, and lighter weight compared to solid blocks. […]