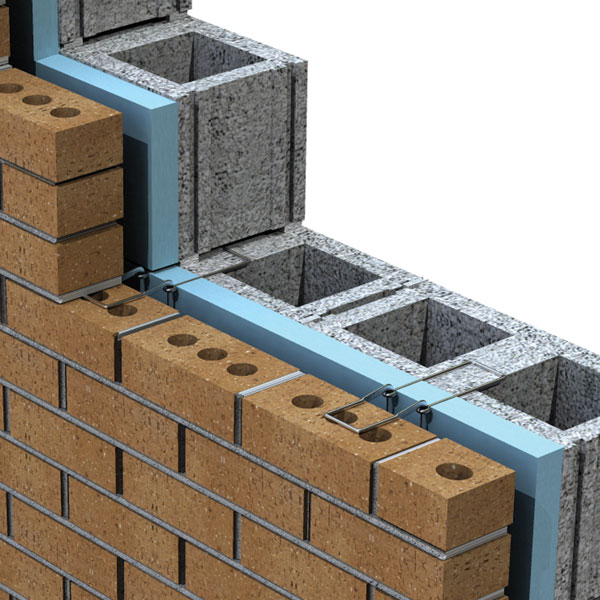

Commonly referred to as “wire,” joint reinforcement is designed to be placed in the horizontal mortar joints of masonry walls.

Uses: Wire is used to control mortar shrinkage and crack control due to temperature and pressure extremes, and bond intersecting walls. Rest assured, regardless of the quality of the mortar and block, this material absolutely necessary.

Types:

- Ladder has a straight cross rod. Ladder reinforcement is typically utilized when rebar is present within the wall as specified by the structural engineer.

- Truss has a diagonal cross rod. Truss wire is approximately 33% stronger than Ladder wire as it includes a transverse wire running the length of the product, but cannot be used with rebar due to this transverse wire. Due to this, it is also slightly more costly.

Dimensions: Wire is always ordered by the block size. When ordering wire for 8″ block, you simple need to ask for 8″ Wire. Out to out spacing is approximately 2″ less than the nominal thickness of the block. Example – 8″ wire will actually measure 6″ wide so it can be placed within the wall.

Wire Gauges: 9 ga= Standard Weight, 3/16″ x 9 ga = Extra Heavy, and 3/16″ x 3/16″ = Super Heavy Duty. In larger gauge wire, the first number is the gauge of the side rods, the second number the gauge of the cross or transverse rod. Always check local building code for specification.

Finishes: Mill Galvanized for interior walls and Hot Dipped Galvanized for exterior walls Galvanization includes the application of Zinc Oxide (.10 oz per square foot of wire for Mill Galvanized, 1.50 oz for Hot Galvanized.) Stainless Steel wire is also available, but is usually utilized in high moisture content areas above 75%, such as a waste water treatment plant.