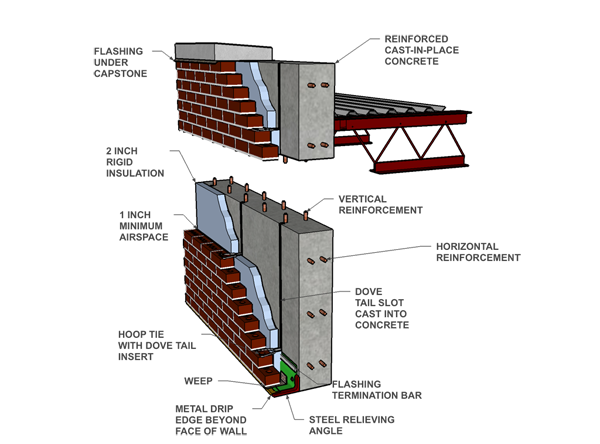

Brick Veneer / Reinforced Cast in Place Concrete

The excellent insulating value and heat capacity of brick and concrete make this system a good choice for schools and commercial buildings.

Recommended Building Types

- Interior partitions, fire separation walls

- Schools, commercial and institutional buildings

- Buildings requiring high fire rating

- Noisy environments

- Areas with frequent rainfall

- Choosing the Right Masonry System for your Budget

Benefits

- Tough, beautiful brick facing over a structural concrete backup system

- Durable, long-lasting wall system

- Minimal long-term maintenance.

- Great design flexibility – use different colors, bond patterns, brick sizes, and surface textures to spice up your design

- Poured concrete backup acts as the structure, with vertical and horizontal reinforcement built into the wall

- Cavity system inherently weatherproof – great for moist environments

- Excellent insulating value and heat capacity

- Inherently fire proof with fire rating of 4 hours

- Great for noisy environments – naturally dampens sound

Special Considerations

- Lower life-cycle costs offset higher initial investment

- This substantial wall system may require larger foundations

- Two trades required for construction – masonry contractor for the façade, and a concrete contractor for the backup – which can make jobsite coordination more complex

- Construction times are longer than for an equivalent masonry (brick on block) wall

- Cast-in-place concrete is not a desirable interior finish. Will need to provide final finished surfaces after wall is built

Definition and Assumptions

Backup: Reinforced 8″ thick concrete wall. #5 reinforcement at 12 inches o.c. each direction, 2 mats of steel

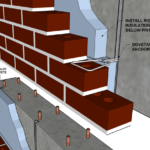

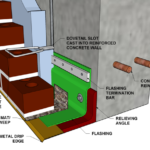

9-gauge triangular ties in dovetail slots embedded in concrete. Install the dovetail slots vertically @ 24″ o.c. Install ties in the slots @ 16″ o.c.

Veneer: Cored modular brick 4″ x 2-1/3″ x 8″ (nom.)

Insulation: 2 inch extruded polystyrene rigid insulation in 3 inch drainage cavity

Flashing: Base Flashing and weeps

Mortar: Type N, Portland cement/lime, plain gray

Joints: Concave tooled

Regional Variations

- When masonry veneer is used in areas of high seismic risk, Veneer ties are required to attach to wire reinforcement embedded in Mortar bed joints in the veneer. Check your local requirements – and save money by using normal Veneer ties in areas of low seismic risk.

Fire Rating (hours)

4 hours

Sound Transmission Class (dB)

STC 64.6

STC=(weight of wall)0.223x21.5

Wall Weight (lb/sq. ft.)

139 lb/sq. ft.

Energy Rating

R-value: 11.1 with 2″ extruded polystyrene rigid insulation (See note)

Calculation:

| Outside Air | =0.17 |

| Brick | =0.44 |

| Air Gap | =0.97 |

| Insulation | =8.00 |

| Gyp board | =0.45 |

| 8 inch concrete | =0.88 |

| Interior Air | =0.68 |

| Total | =11.14 |

Note: The type of rigid insulation you install affects the wall’s insulating capacity (the R-value). Polyisocyanurate insulation gives you 8.0 R per inch (or 12.0 R for 1.5″). Extruded polystyrene insulation is worth 4.0 R per inch (6.0 R for 1.5″). Expanded polystyrene yields 5.0 R per inch (7.5 R for 1.5″). Use either thicker insulation or more expensive polyisocyanurate to achieve a higher rating

Sustainability & LEED

- Energy efficiency, thermal comfort and energy analysis – up to 10 pts

- Innovation and design – 1 pt

- Recycled content – 2 pts

- Regional material (where applicable) 2 pts

- Renewable energy and thermal mass – up to 10 pts

- Sustainablility and Brick

Design Tips

- Place rigid-board insulation in the drainage cavity to maximize interior usable space, and take advantage of the huge thermal mass provided by the concrete backup system

- brick veneer expands as it ages, whereas concrete shrinks. Don’t forget to detail control joints in the brick veneer and control joints in the concrete backup

Construction Tips

- Back bevel Mortar joints to prevent excess Mortar from falling into the drainage cavity

- Dovetail slots are expensive for the concrete contractor to install and are often left out. You may need to face-mount dovetail slots using anchors installed into the concrete