SRW Design: Expert Level

Are you an architect, engineer, or contractor looking for more technical information as you design and install a segmented retaining wall (SRW)?

Guidance Manual

NCMA Guides

One of the best places to look for more information on SRW construction is the National Concrete Masonry Association (NCMA)

- Installation Guide

- Best Practices Guide (2016) Some parts of the Best Practices Guide have been pulled out and highlighted below to address common questions.

- NCMA SRW Design Manual (2009)

- Design Details (CAD files)

- Inspection Guide

Software Tools

Interested in designing an SRW, but don’t want to do the reading. There are several good software packages out there

Design Standards of SRW Block (ASTM C1372)

- Dimensional tolerances: ±1/8 in. (except for architectural finished surfaces)

- Minimum Compressive Strength = 3,000 psi

- Maximum Absorption = 15 – 18 pcf

Freeze-Thaw Resistance of SRW Block (ASTM C1262)

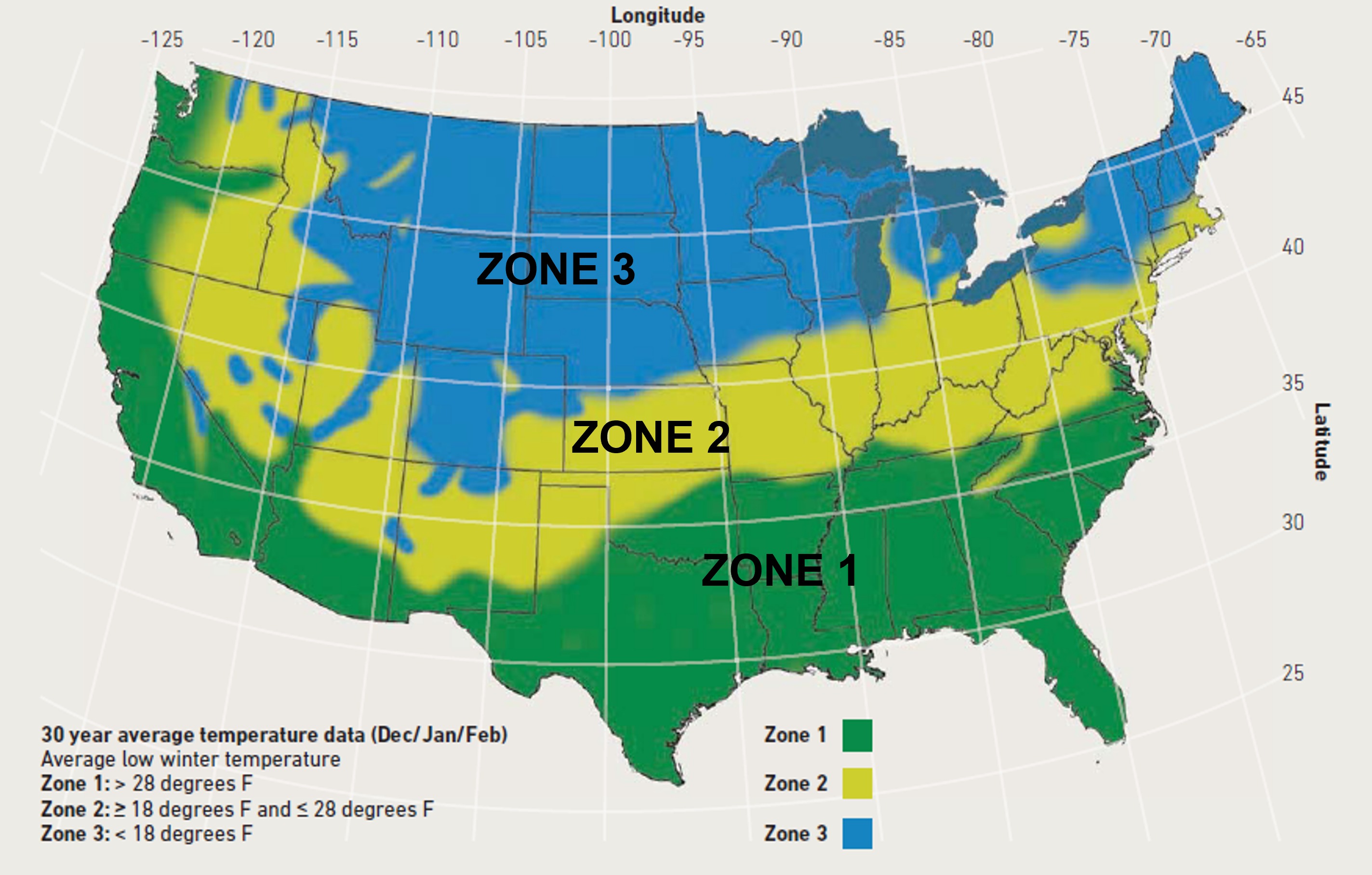

| Exposure Zone | SRW Properties | Freeze/Thaw Testing (C1262) |

| Zone 1 and Non-Roadway Applications | ASTM C1372 | None |

| Zone 2 –

no/negligible de-icing salt exposure1 |

ASTM C1372 | Proven field performance or test in water:

•≤1% wt. loss in 5 of 5 samples after 100 cycles; or •≤1.5% wt. loss in 4 of 5 samples after 150 cycles. |

| Zone 2 –

de-icing salt exposure |

ASTM C1372, plus

• Targeted compressive strength: 4000 psi • Targeted absorption: 7 pcf |

Test in 3% saline solution:

•≤1% wt. loss in 5 of 5 samples after 20 cycles; or •≤1.5% wt. loss in 4 of 5 samples after 30 cycles. |

Note: Only Zone 1 & 2 are shown because Ernest Maier does not service any regions that fall in Zone 3. Please see the Best Practices Guide for more information.

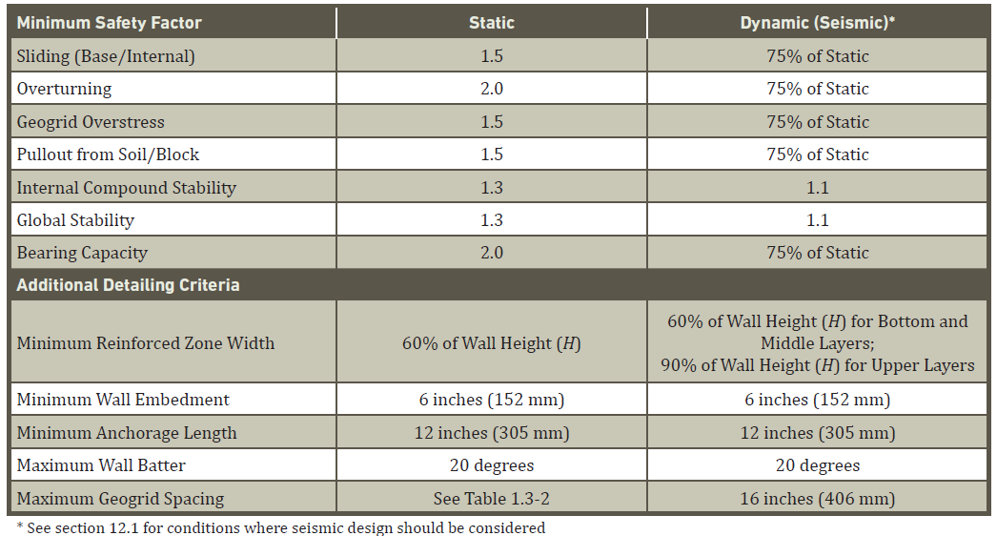

Minimum Design Standards

Appropriate design of an SRW should include a minimum safety factor. These are the minimum recommended safety factors.

Geosynthetic Reinforcement

Design Guidance

Use these design tables to understand how much reinforcement to place in your SRW

| Wall Height ft (m) | Reinforced Zone Material | Design and Layout Criteria | ||||

| Gradation | Plasticity | Reinf. Spacing, Max. | L/H, min. | Gravel Fill Thickness in. (mm) | ||

| H ≤10

(H ≤ 3) |

Recommended | See Table Below | Moderate | 24 in. | 0.6 | 24 in. (610 mm) from face

12 in. (305 mm) behind unit |

| Alternate | See Table Below

#200 waived |

Moderate | 16 in. | 0.7 | 30 in. (762 mm) from face

18 in. (457 mm) behind unit |

|

| 10 < H ≤ 20

(3 < H ≤ 6) |

Recommended | See Table Below | Low | 24 in. | 0.6 | Top 10 ft (3 m) same as

above, remainder 36 in. (914 mm) from the face, 24 in. (610) behind unit |

| H > 20

(H > 6) |

Recommended | See Table Below | Low | 24 in. | 0.6 | Top 10 ft (3 m) and lower 10

ft (3 m) to 20 ft (6 m) same as above, remainder 48 in. (1219 mm) from the face, 36 in. (914 mm) behind unit |

| Sieve Size | Percent Passing (Short/Medium Walls) | Percent Passing (Tall Walls) |

| 1 in. (25 mm) | 100 | 100 |

| No. 4 | 100 – 0 | 100 – 20 |

| No. 40 | 0 – 60 | 0 – 60 |

| No. 200 | 0-35 | 0-15 with PI<6 |

Material Choice

The proper use of geosynthetics, can compensate for many other imperfections, mistakes, or oversights in the design of an SRW. Be sure to select materials that provide the recommended material strength and are permeable to water.

An interesting application that showcases the power of geosynthetic reinforcement is: Geosynthetic Reinforced Soil- Integrated Bridge Systems (GRS-IBS). These are basically just SRW blocks with geotextiles every layer that are used for smaller bridges <140’ spans. These solutions are accepted by the FHWA and DOTs around the country.

Geosynthetic Reinforced Soil Integrated Bridge System

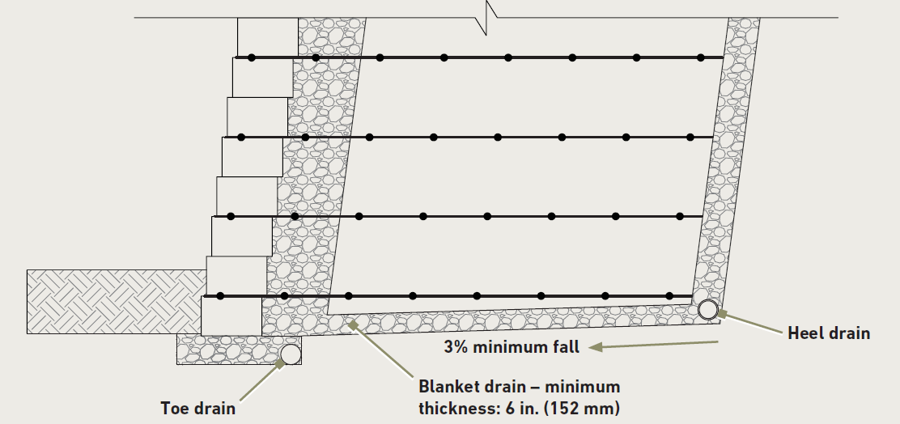

Drain Design

There are several drainage design options

- Blanket Drain- runs underneath the reinforced soil zone- used to address the presence of migratory subsurface water

- Toe Drain- located behind/below the SRW blocks- removes water from behind the blocks

- Heel Drain- located at the base of the interface of the reinforced and retained soil zones- drainage structure to further reinforce the

- Chimney Drain- located at the interface of the reinforced and retained soil zones- used to address high water tables or the presence of migratory subsurface water

Toe and Heel Drain Detail

Chimney and Blanket Drain Details

Ernest Maier, Gomoljak Parker Block, and Skyline Brick have professional sales representatives who in many cases have served as contractors and installers ourselves. Feel free to reach out with your questions.

VP of Business DevelopmentAaron Fisher

Latest News

How Long Does Type S Mortar Take To Cure?

Like all mortars, Type S mortar requires careful attention during the curing process to reach its full strength. This isn’t […]

Decorative Downspout Splash Block Ideas For A Stylish Exterior

Creating a stylish exterior involves paying attention to the smallest details, and downspout splash blocks can make a surprising difference. […]

A Stormwater Compromise to Nowhere

I went to visit my grandmother at her new apartment and drove past an atrocity of a stormwater/transportation compromise. It […]

Choosing The Right Size: Your Essential Concrete Lintel Size Guide

Choosing the right size for a concrete lintel is a critical decision that can significantly impact the structural integrity of […]