5 Effective Ways to Prevent Cracks in Concrete

Concrete is a popular choice in the construction industry due to its strength, durability, and versatility. However, over time, concrete is prone to developing cracks. While some cracks may be superficial, they can also indicate underlying structural damage that can worsen if not addressed promptly. As the saying goes, “an ounce of prevention is worth a pound of cure.” Instead of waiting for cracks to occur, it is crucial to take preventive measures since repairs can be time-consuming and costly. Follow these five ways to effectively prevent concrete cracks:

Use High-Quality Concrete

Before starting any concrete project, ensure that you use high-quality concrete. Cheap and poor-quality concrete is more susceptible to cracking, particularly if it is not properly mixed. Choose a reliable supplier and opt for the highest quality concrete available.

Prepare the Site

Never overlook the importance of site preparation. To prevent cracks, clear out any organic matter or debris from the area before commencing your concrete project. Additionally, level and compact the ground thoroughly. Proper site preparation ensures a seamless pour, resulting in strong, durable concrete that is resistant to cracks.

Add Reinforcement

Reinforcing concrete enhances its strength and durability, effectively preventing cracks. In most concrete projects, bars, mesh, or fibers (typically made of steel or fiberglass) are added to provide support. Consult with a professional to determine the appropriate reinforcement material for your specific project.

Properly Mix the Concrete

It is crucial to follow the manufacturer’s instructions when mixing concrete. This ensures that the concrete is durable and minimizes the risk of cracking. Avoid adding excessive water, as it weakens the concrete and makes it more prone to cracks. Follow these steps for optimal results:

- Use the recommended proportions provided by the manufacturer.

- Use clean materials free from dirt and contaminants.

- Thoroughly mix the concrete using a consistent method.

- Test the mix to achieve the desired consistency and strength.

Implement Proper Concrete Curing

After pouring the concrete, proper curing is essential to prevent cracks. Control the curing process by following these guidelines:

- Maintain humidity near the exposed faces of the concrete. Consider covering the concrete with a moisture-retaining material or curing blanket to ensure uniform curing. Do not add water directly to the concrete mix beyond the manufacturer’s recommendation.

- Avoid exposing the concrete to extreme temperatures. High or low temperatures can make the concrete more susceptible to cracking. Avoid pouring concrete in extremely hot or cold weather.

- Use a curing compound. Apply curing compounds to the concrete’s surface to retain moisture and prevent crack formation.

- Monitor the curing process to ensure the concrete remains moist and no cracks develop.

If you require guidance on a concrete project, don’t hesitate to contact us at Parker Block and Bay Ready Mix. We are here to assist you and provide expert advice.

Concrete Sales AssociateNatalie Jaimes

Latest News

Building a Better Sea Wall

Waterfront property is the best: sea breezes, water access, and views. Unfortunately water and shoreline are always in a bit […]

Stop Building Tunnels for Stormwater

Engineers love big projects. They are statements of competence, and also make big money. However, bigger isn’t always better and […]

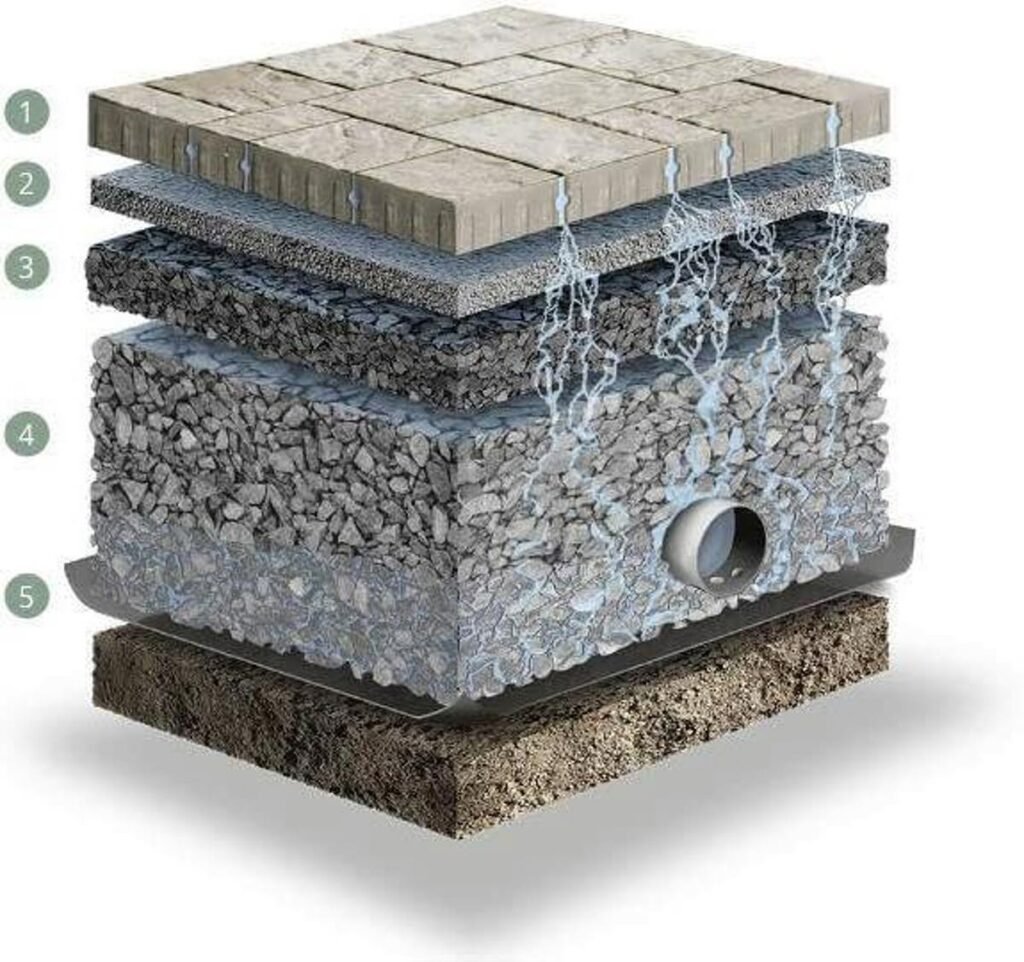

Understanding The Installation Costs Of Permeable Pavement

Permeable pavement has emerged as a leading solution in modern construction, known for its environmental benefits and ability to manage […]

What Accessories Do You Need For Working With Concrete?

Working with concrete is an integral part of construction, whether it involves laying foundations, building structures, or creating pathways. The […]