Answering 6 FAQs About Fiberglass Rebar

Demand for glass fiber reinforced polymers (GFRP), aka fiberglass rebar, has been growing as an innovation over steel rebar and wire in concrete. Replacing steel with fiberglass rebar reduces problems associated with steel corrosion, including the high costs of applying and touching up epoxy coatings to steel. If you are considering using Fiberglass Rebar in your next project, here are some FAQs to help you get started.

What is Fiberglass Rebar?

Fiberglass Rebar is a cost-competitive alternative to steel rebar. It is made from high-quality glass fibers, polyester resin, or vinyl ester with a >75% fiber content through a continuous process of pultrusion. As such, it is resistant to corrosion, lightweight, and delivers high performance.

Several manufacturers offer such products, and it’s available wherever you buy construction materials, including big box stores.

What are the Properties of Fiberglass Rebar?

Besides being resistant to corrosion, it is also unaffected by alkaline environments (concrete is a strong base). It is non-magnetic, so it will not interfere with electronic instruments.

In comparison to steel rebar, fiberglass rebar has the following qualities:

- Tensile strength: Due to the unique anisotropic property of composites, GFRP has a higher yield strength than traditional steel rebar.

- Conductivity: Not electrically and thermally conductive. Thus, reducing accidents associated with unintentional electrical current and reducing cold bridges.

- Weight: Lighter than steel rebar, making it easier to handle on-site.

- Modulus of Elasticity: GFRP has a relatively low modulus of elasticity closer to the modulus of concrete.

Is Fiberglass Rebar Cost Competitive?

Yes, fiberglass costs less than plain steel.

Aside from material savings, there are significant labor savings to be realized during the installation. Fiberglass rebar is about 75% lighter than steel rebar, so it costs less to ship. When installing this option, it is easier to handle and cut. There is no need for waterproofing additives, no allowances required for corrosion diameter reduction, and no need for extra concrete protection. Furthermore, there is no need for touch-ups of the surface coating or cathodic protection. This means GFRP reduces installation time and labor costs.

Can Fiberglass Rebar Be Bent or Cut On-Site?

There is some flex in GFRP, allowing you to make large radius bends on-site. Small radius bends or customized shapes are manufactured and cured at the factory, with standard options stocked on site. We recommend you speak with one of our experienced team members at Ernest Maier to discuss fabrication and take-offs.

Cuts are quick and simple to make with a diamond blade.

Does Fiberglass Rebar Require Any Special Handling?

Similar to handling steel rebar, putting on your safety gear when working with fiberglass rebar is essential. Wear gloves to prevent abrasion or cuts; put on dust masks and safety goggles when cutting the bars.

When Should I Use Fiberglass Rebar in Projects?

Fiberglass is a suitable replacement for any place steel rebar or mesh is used. Fiberglass excels in applications that need high strength and are exposed to harsh environmental conditions. This includes sea walls, medical facilities, and roadways.

It is a non-conductive, non-magnetic building material ideal for medical and scientific facilities, light rail projects, electrical substations, and compass calibration pads at the airport.

VP of Business DevelopmentAaron Fisher

Latest News

Building a Better Sea Wall

Waterfront property is the best: sea breezes, water access, and views. Unfortunately water and shoreline are always in a bit […]

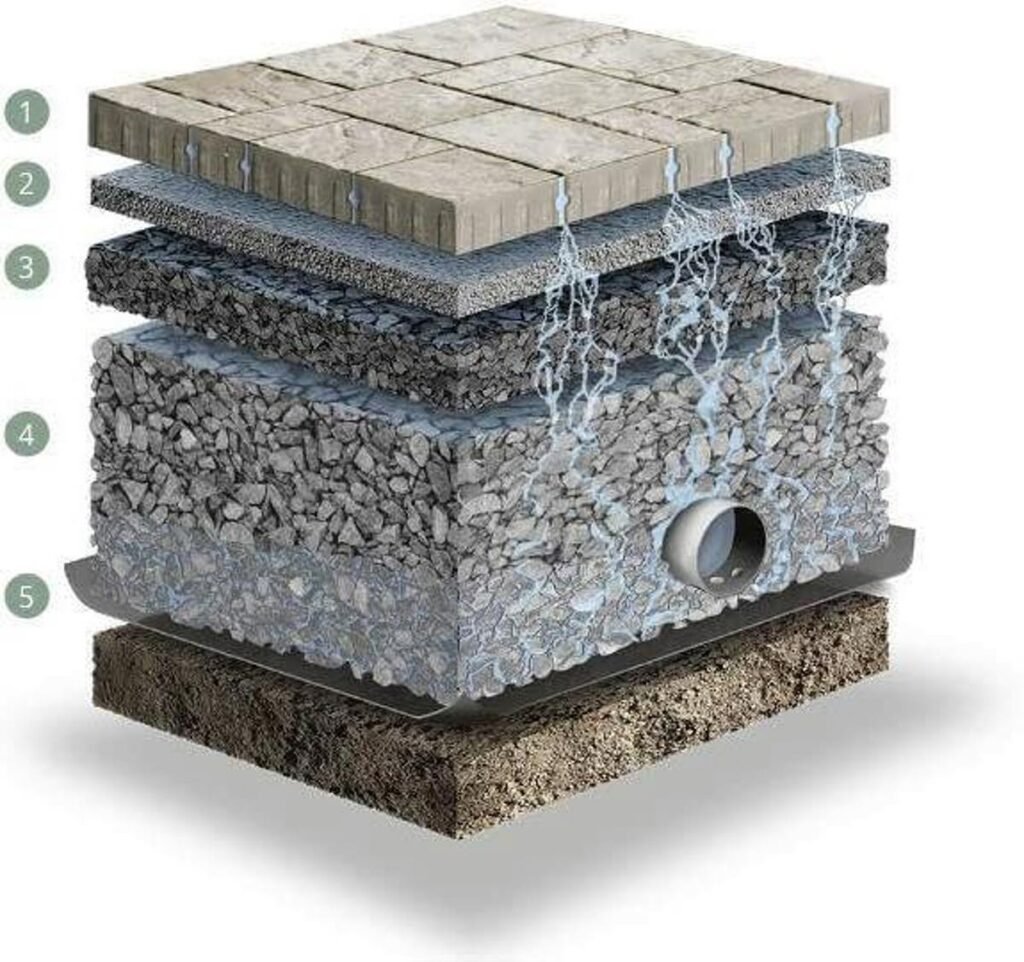

Stop Building Tunnels for Stormwater

Engineers love big projects. They are statements of competence, and also make big money. However, bigger isn’t always better and […]

Understanding The Installation Costs Of Permeable Pavement

Permeable pavement has emerged as a leading solution in modern construction, known for its environmental benefits and ability to manage […]

What Accessories Do You Need For Working With Concrete?

Working with concrete is an integral part of construction, whether it involves laying foundations, building structures, or creating pathways. The […]