Lumber: Not as Green as Advertised

Annually concrete accounts for 2.8 billion tons of CO2 emissions (8% of global emissions). However, wood products amount for 3.5 billion tons of CO2 emissions (10% of globally). (Source: WRI report, ClimateWatchData.org, The Guardian). While not all wood products are destined to become lumber, it’s a clear wake-up call to not jump out of the pot and into the frying pan if we are to tackle the built environment’s embodied carbon emissions by abandoning concrete. It is not going to be as simple as building everything out of wood.

There are a few factors at play here that merit discussion

- The True Environmental Cost of Lumber Harvesting

- The Knock-On Environmental Costs

- Mass Timber is not your Father’s 2×4

The True Environmental Cost of Lumber Harvesting

Trees borrow carbon they don’t permanently store it.

Sustainable forestry is possible, but it often does not recognize the financials of what is otherwise a commodity good. That is the only valuable part of the forest are the tree trunks big enough to be made into lumber. The branches, the leaves, the undergrowth, and other residuals are of limited value. As such they are either left were they are cut or are burned. According to the lumber industry’s own Product Category Rules: “Forest residuals and soil carbon fluxes are excluded from the GWP characterization methodology.” You can’t ignore one aspect of sustainability, because it inconveniences you.

The loss of canopy also dramatically alters the impact of rain and runoff. Topsoil which is rich in nutrients and carbon can now be carried away. This decreases the quality of the soil to grow plants, and causes dead zones downstream in bodies of water.

The assumptions around carbon neutrality depend on the continuous use of the same acreage. However, old growth trees make better lumber. Sustainable forestry is possible, but it prioritizes keeping existing forests and the stored carbon and nutrients in them.

The Knock-On Environmental Costs

Managing forests indicates a clear paternalistic approach that has oft resulted in problems.

Dense plantings of trees increase productivity of an acre, but also provide more tinder for a forest fire. This has become a particularly salient fact in cities well removed from the logging industries. As San Francisco and New York City have both had to deal with separate plumes of smoke that made the outside air unbreathable.

This is also a problem in a world in which climate change is driving extreme drought and rainfall. Trees handle these extreme conditions poorly and too much or too little water could kill the tree, wasting years of growth. Without regular and consistent rainfall, plants become stressed and do not grow as strong. And while CO2 will be more plentiful, leading to growth—the lack of any needed input will cause problems.

When we grow and manage forest for lumber, we do monocultures—single types of trees. This is great for getting a uniform product at the end, but it less than ideal for a resilient natural environment. It allows pests and disease to spread quickly, while providing less diversity and variability in animals and habitats. And this isn’t a hypothetical, the Mountain Pine Beetle has killed 100+ million acres of forest in North America.

Mass Timber, Not Your Father’s 2×4

Mass timber is a group of structural lumber products that involve more than simply cutting a tree into a shape. It includes: Cross Laminated Timber (CLT), Glued Laminated Timber (Glulam), Laminated Veneer Lumber (LVL) among others. The basics are that the fibers in the wood are arranged in layers, and they are glued together. Depending on the arrangement of the fibers these products an be used for slabs, load-bearing walls, framing, and beams. While the product looks like wood there is a significant portion of these products that is essentially glue.

Furthermore one of the challenges is the where of fabrication and the supply chain; many of these products are not harvested, manufactured, and sold locally. That is the wood might be harvested in Canada, shipped to China for manufacturing, and then shipped to the USA to be installed. Logistics matter in terms of carbon emissions and building sustainable communities.

Despite the advantage of being a natural product, these materials only come out slightly ahead of concrete on an equivalent structural/functional basis. To be clear this is the average building, and does not begin to account for any of the efforts to make lower carbon concrete or concrete’s inherent advantages in terms of energy efficiency, longevity, or resilience.

These numbers are from someone trying to sell Mass Timber (https://www.oneclicklca.com/structural-timber-ecodesign-in-practice/)

All Things Being Equal

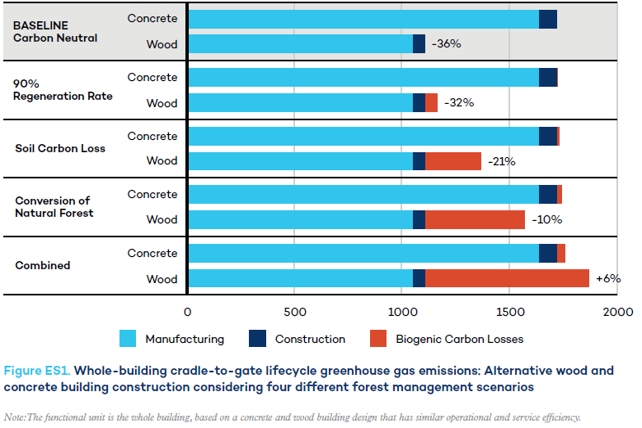

To be fair researchers and policymakers have begun to account for just such considerations when looking at the whole structure (Source). Simply put, concrete and wood are pretty similar:

Source: International Institute for Sustainable Development | IISD.org

So next time someone says something is more sustainable, dig a bit deeper

VP of Business DevelopmentAaron Fisher

Latest News

4 Features That Makes Masonry Supply Company Stand Out

A masonry supply company plays a crucial role in the success of construction projects, providing essential materials and expertise to […]

Choosing The Right Size Lintel For Your Project

Determining the correct size of a lintel is critical for the stability and longevity of your construction project. A lintel […]

Data Misses on Embodied Carbon

There is significant urgency to avoid, reduce, or even reverse the emissions of greenhouse gases (CO2e) to avoid the worst […]

4 Masonry Tools You Should Have At Home

Effective and efficient masonry work, whether for repairs or new projects, requires the right tools. At home, having a basic […]