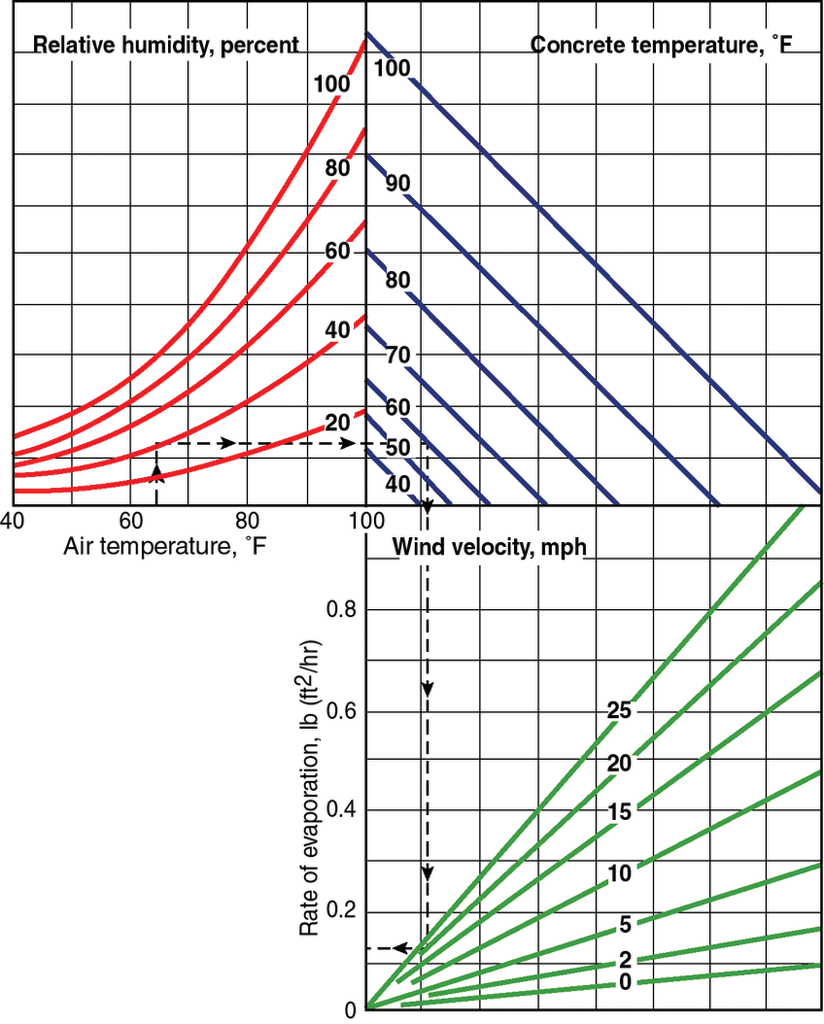

Plastic Shrinkage Cracking

Plastic shrinkage cracks appear in the surface of fresh concrete soon after it is placed and while it is still plastic. These cracks appear mostly on horizontal surfaces. They are usually parallel to each other on the order of 1 to 3 feet apart, relatively shallow, and generally do not intersect the perimeter of the slab. Plastic shrinkage cracking is more likely to occur when high evaporation rates cause the concrete surface to dry out before it has set.

Plastic shrinkage cracks are unsightly but rarely impair the strength of concrete floors and pavements. These cracks, however, can permit the ingress of other aggressive chemicals that impact durability and as weak points for the initiation of later age cracking due to other reasons. The development of these cracks can be minimized if appropriate measures are taken prior to and during placing and finishing concrete. Note:

Source: ACI 305R-10, Guide to Hot Weather Concreting

How to Use:

- Begin with air temperature and move up to the relative humidity

- Move right to concrete temperature

- Move down to wind velocity

- Move left to read approximate rate of evaporation

Whenever the chart predicts water will evaporate at a rate approaching 0.2 pounds/square foot/hour (lbs./sq. ft./hr.), the likelihood of plastic shrinkage cracking exists. Of course, other factors, such as elevated air content in the concrete or the presence of fly ash or microsilica, also affect the occurrence of plastic shrinkage cracks. However, ACI’s nomograph is a pretty fair indicator for everyday concrete.

What can you do to minimize plastic shrinkage cracking

- Dampen the subgrade and forms when conditions for high evaporation rates exist.

- Prevent excessive surface moisture evaporation by providing fog sprays and erecting windbreaks.

- Cover concrete with wet burlap or polyethylene sheets between finishing operations.

- Use cooler concrete in hot weather and avoid high concrete temperatures in cold weather.

- Cure properly as soon as finishing has been completed.

Need a more accurate estimate on the evaporation rate? Check out the ACI Mobile app

Ready Mix Sales ManagerDavid Welch

Latest News

Building a Better Sea Wall

Waterfront property is the best: sea breezes, water access, and views. Unfortunately water and shoreline are always in a bit […]

Stop Building Tunnels for Stormwater

Engineers love big projects. They are statements of competence, and also make big money. However, bigger isn’t always better and […]

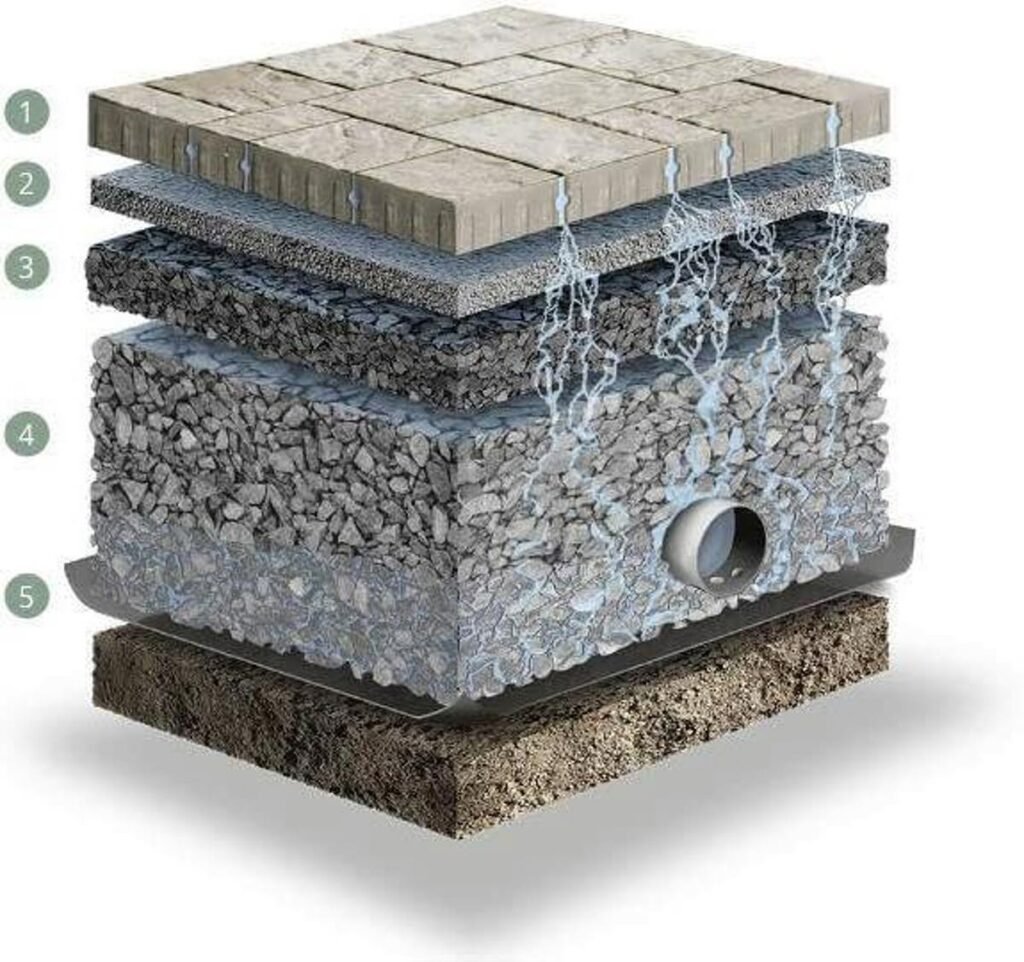

Understanding The Installation Costs Of Permeable Pavement

Permeable pavement has emerged as a leading solution in modern construction, known for its environmental benefits and ability to manage […]

What Accessories Do You Need For Working With Concrete?

Working with concrete is an integral part of construction, whether it involves laying foundations, building structures, or creating pathways. The […]