How To Cut Rigid Foam Insulation Like A Pro

Rigid foam insulation is a top choice for creating an energy-efficient barrier when insulating your home. However, the effectiveness of this insulation is only as good as the installation, and that begins with a precise cut. Knowing how to cut rigid foam insulation properly is crucial for do-it-yourself homeowners and professional builders alike. A clean, accurate cut ensures that the insulation fits snugly in place, eliminating gaps that can compromise thermal performance. This guide will walk you through the steps and techniques to cut rigid foam insulation like a pro, covering everything from selecting the right tools to the final adjustments for a perfect fit. With the right approach, you can ensure that your insulation project contributes to a more comfortable, cost-effective home.

Understanding Rigid Foam Insulation

Rigid foam insulation is a type of building insulation that comes in large boards or panels. It’s made from materials like polystyrene, polyisocyanurate, and polyurethane. These panels are known for their high insulating values relative to thickness, making them a popular choice for energy efficiency in home construction and renovation. Cutting these materials accurately is essential to maintain their insulative properties and ensure they fit snugly into the space they are meant to insulate. A poorly cut insulation can lead to gaps, compromising the building envelope, and dramatically reducing the material’s effectiveness.

Selecting the Right Tools for Cutting

A sharp utility knife is your most basic and important tool. It can make clean cuts through thinner panels of rigid foam. For thicker panels, a saw may be necessary. A fine-tooth saw can create smooth edges and reduce the amount of foam dust. For the best results, some professionals use a hot wire cutter, which melts through the foam, leaving a clean edge without producing any dust. Regardless of the tool, it should be handled with care to ensure safety and precision in cutting.

Measuring and Marking for Accurate Cuts

Before cutting, measure the space where the insulation will be placed and then transfer these measurements to the insulation panel. Use a straight edge to draw a line for the cut. A T-square can be particularly useful for ensuring the lines are straight and the corners are square. Precise measuring and marking are vital; even a small mistake can lead to a poor fit, compromising the insulation’s efficiency.

Cutting Techniques for a Professional Finish

The technique used to cut rigid foam insulation can make a difference in the quality of the final installation. When using a utility knife, score the line you’ve marked on the foam, then snap the board along the line for a clean break. If using a saw, keep the blade perpendicular to the foam to ensure the edge is straight, which is necessary for a tight fit against other panels or building materials. If a hot wire cutter is available, make precision cuts without the mess. After cutting, check the fit of the insulation in its intended space and trim as necessary for a professional-grade installation. Remember to wear appropriate safety gear, such as gloves and a dust mask, to protect against sharp edges and foam dust.

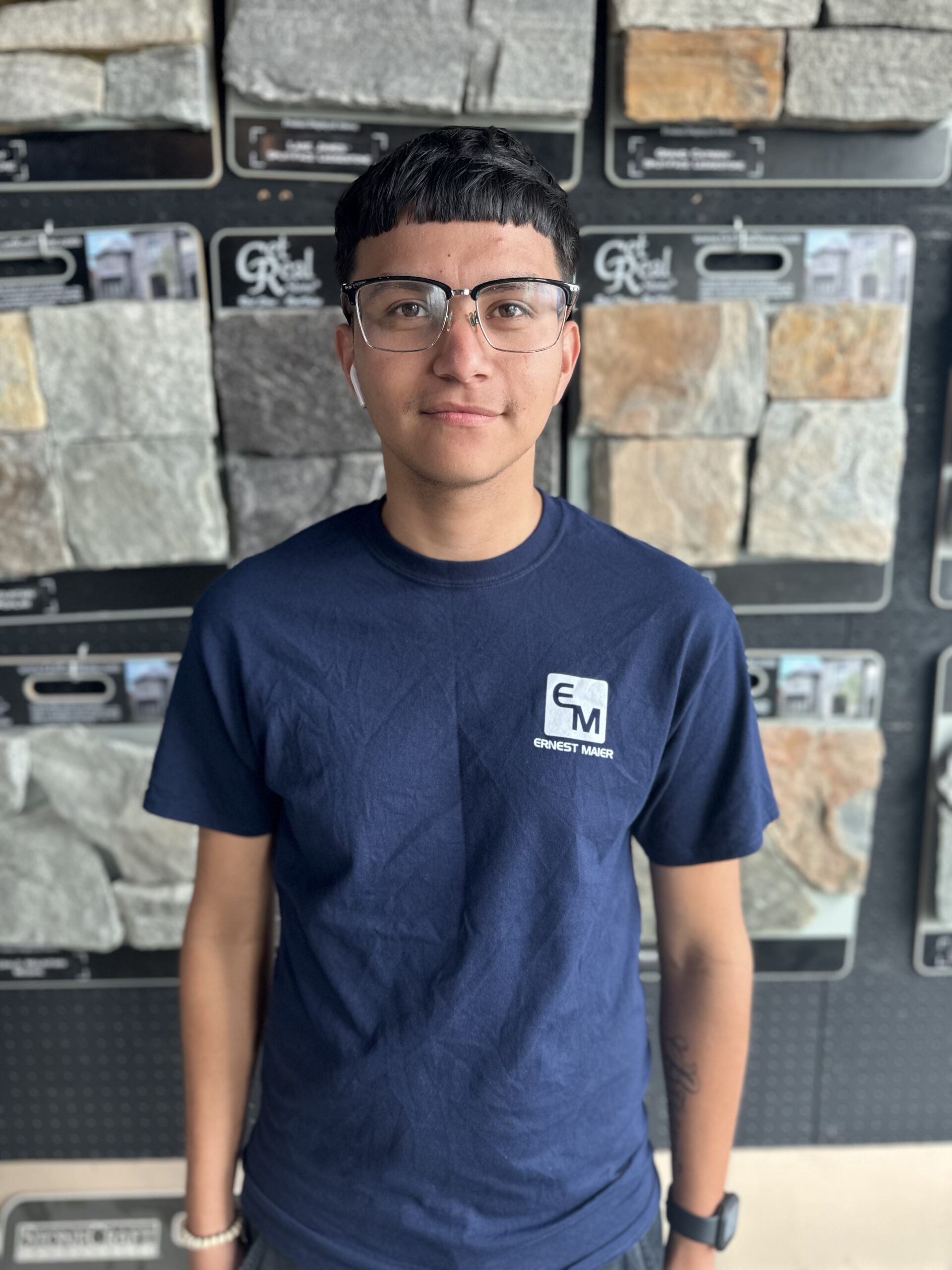

Counter SalesJonathan (JB) Monterroza

Latest News

4 Ways To Reinforce Concrete

Concrete is one of the most fundamental materials used in construction. If you’re working on a domestic project or a […]

The Environmental Benefits Of Using Ready-Mix Concrete

The construction industry is changing quickly to meet the growing demand for sustainability and eco-friendly practices. One of the most […]

6 Essential Tips For Grouting Stone Veneer

Grouting stone veneer is an important step in the installation process that can significantly impact the overall look and durability […]

Should You Fill Hollow Concrete Blocks?

Hollow concrete blocks are widely used in construction due to their strength, versatility, and lighter weight compared to solid blocks. […]