How Fiberglass Rebar Handles Natural Problems

Fiber Reinforced Polymer (FRP) can be used to strengthen and reinforce structures due to the way it is created. Typical FRP materials are polymer matrixes reinforced with fibers from glass, basalt, aramid, or carbon. As a lightweight, corrosion-resistant, and heat-resistant product, FRP rebar is the ideal solution for concrete projects due to its composition. Fiberglass rebar – the lowest cost option – is perfect for a variety of concrete projects, including sea walls, bridges, garages, and wharves.

If you are looking to utilize fiberglass rebar for your structures, you are on the right track! Read on to learn more about fiberglass vs natural problems.

Fiberglass Rebar’s Ability to Withstand High Temperatures and Fire

Fiberglass rebar’s ability to resist high temperatures comes from two factors: 1) Its thermal and electrical insulating properties. The former prevents the propagation of localized temperature extremes throughout the rebar reinforcement, while the latter avoids the detrimental effects of heat-generating stray current. 2) Concrete cover, which further insulates the material, giving it sufficient fire rating.

Fiberglass Rebar’s Ability to Withstand Low Temperatures and Water

Due to its inert nature, FRP can withstand all environmental conditions, including rain and cold. In contrast to steel, which cannot handle salts, acids, or other corrosive elements, FRP is the most appropriate material for concrete structures that need to be resistant to these elements.

It is therefore best to choose fiberglass rebar when considering building materials for marine concrete structures.

Fiberglass Rebar and its Ability to Stay Corrosion and Rust Free

Iron oxide, also known as rust, forms when iron in steel reacts with water and oxygen—a chemical process called corrosion. Materials deteriorate due to this chemical reaction. Therefore, glass fiber-reinforced polymers have gained considerable ground over steel in applications where corrosion is a major concern.

Corrosion can be effectively managed with fiberglass rebar. When exposed to chloride-rich conditions, fiberglass rebar-reinforced concrete does not react. Engineers rely on FRP for construction applications due to its corrosion-resistant and stress-free nature.

Fiberglass Rebar and its Ability to Stand the Test of Time

In comparison to traditional reinforcement materials such as black steel rebar and epoxy-coated rebar, fiberglass rebar has proven to be a great alternative. Concrete structures cannot be maintained in good condition using traditional reinforcement techniques. In the long run, deteriorating reinforcement can end up costing you a lot of money.

Fiberglass rebar is an economical way to ensure a long service life for your building by saving you money and time in the long run.

Conclusion

In general, fiber reinforced polymers are known for their durability and prove to do just what they claim. Now that you know how fiberglass rebar handles natural problems, you will feel confident about your building or structure. You can trust a concrete reinforcement product that can withstand nearly anything it encounters, from fire to continuous waves and any other natural problems.

VP of Business DevelopmentAaron Fisher

Latest News

Building a Better Sea Wall

Waterfront property is the best: sea breezes, water access, and views. Unfortunately water and shoreline are always in a bit […]

Stop Building Tunnels for Stormwater

Engineers love big projects. They are statements of competence, and also make big money. However, bigger isn’t always better and […]

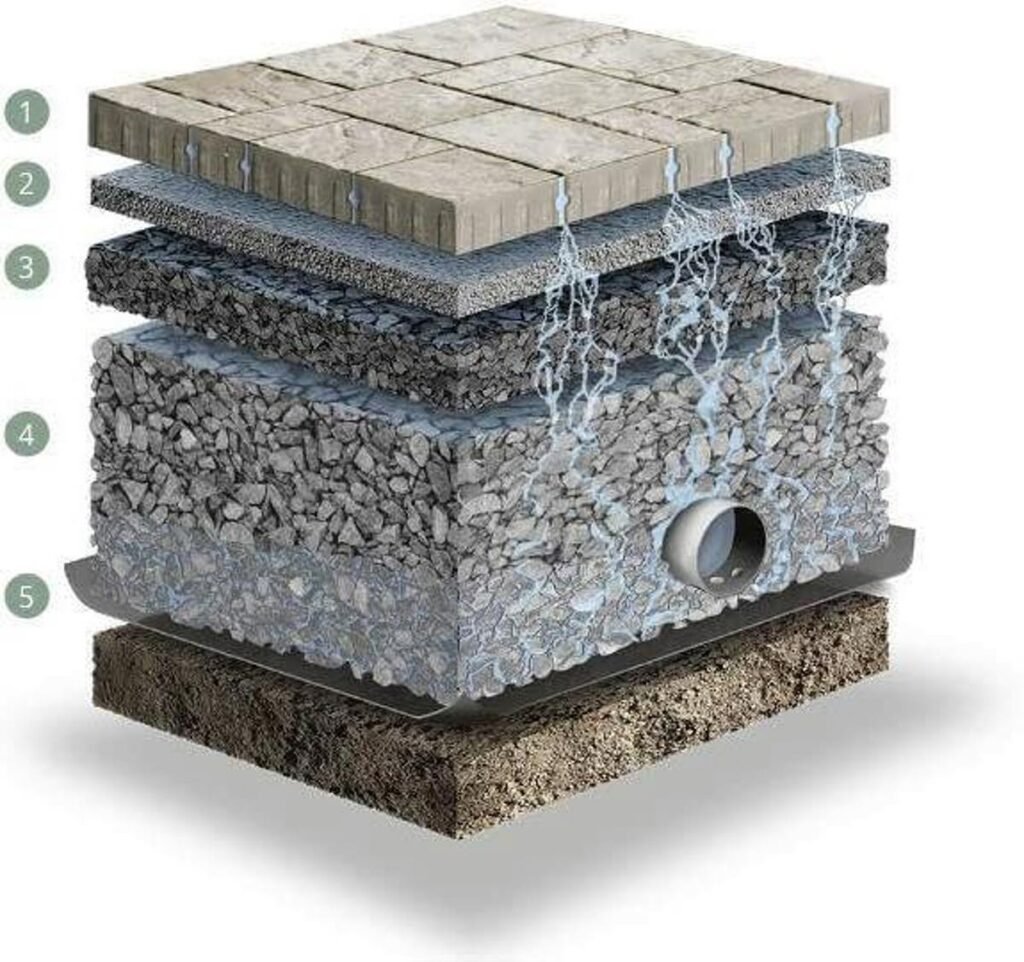

Understanding The Installation Costs Of Permeable Pavement

Permeable pavement has emerged as a leading solution in modern construction, known for its environmental benefits and ability to manage […]

What Accessories Do You Need For Working With Concrete?

Working with concrete is an integral part of construction, whether it involves laying foundations, building structures, or creating pathways. The […]